Wuxi Yushun Metallurgy Technology Co., Ltd is a comprehensive

enterprise integrating scientific research and development,

engineering design, system integration, equipment installation,

sales service, we serve numerous iron and steel enterprises

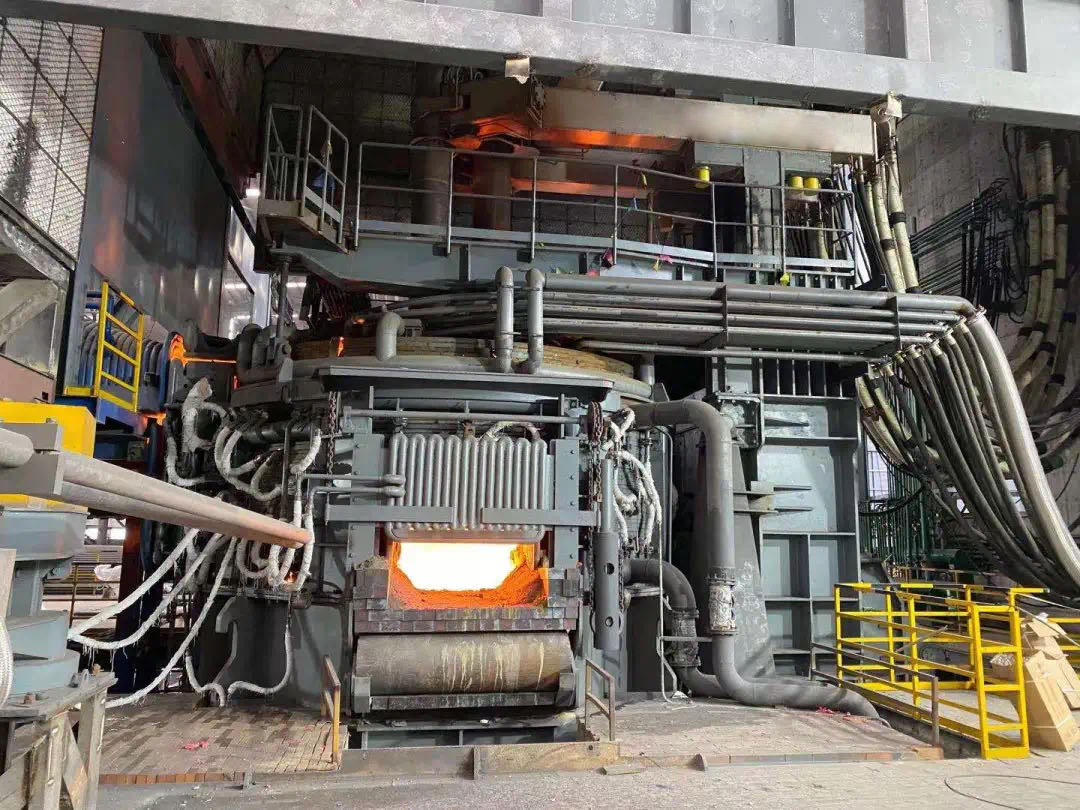

domestic and overseas. Main projects include design and manufacture

of technology, machinery, fluid, electric control for steel-making

equipment, steel rolling equipment and steel deep processing.

We have professional from related area, experienced engineering

technicians from design and research institute, iron and steel

enterprise, we can joint research and development with domestic

excellent enterprises with good technology and rich practical

experience in metallurgical industry, customize high, intermediate

and low grades configurations of production line or single

equipment, provide overall design for smelting, continuous casting

and steel rolling to meet the production requirements of low power

consumption and high efficient, we also can contract turnkey

project.

Wuxi Yushun Metallurgy Technology Co., Ltd takes the concepts of

“customer first, technology-based” and meets the demands of

customer including design, manufacture, installation, pre-sales

guidance and after-sales service.

Choosing Wuxi Yushun Metallurgy Technology Co., Ltd as partner

means choosing trust and guarantee, we can help your career

development, let’s cooperate and create the future together.

Sincerely welcome your presence and guidance.

Client Meeting